Product Category

- Water filling machine

- Juice drink filling machine

- Soft drink filling machine

- Easy open can filling machine

- Glass bottle filling machine

- 3&5 gallon filling machine

- Beer filling machine

- Oil filling machine

- Bottle blow molding machine

- Blowing filling capping combiblock machine

- Bottle labeling machine

- Finished product packing machine

- Injection molding machine

- Material

- Accessory equipment

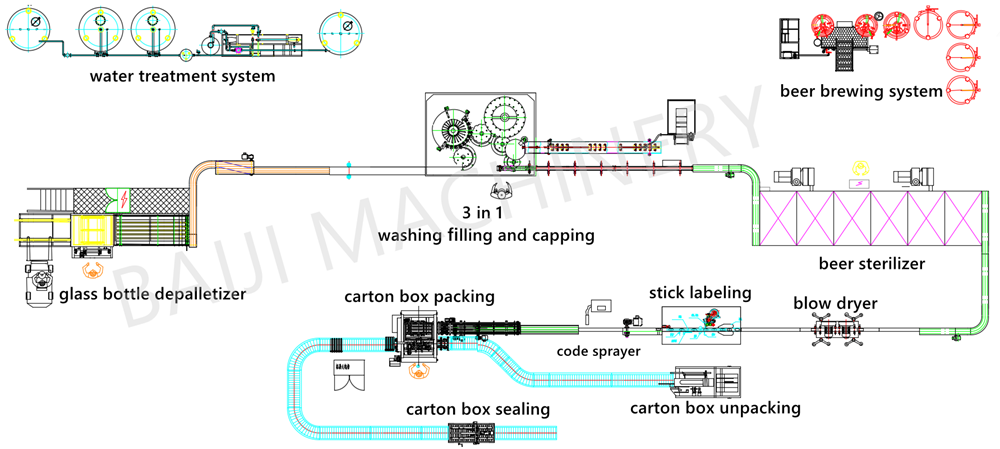

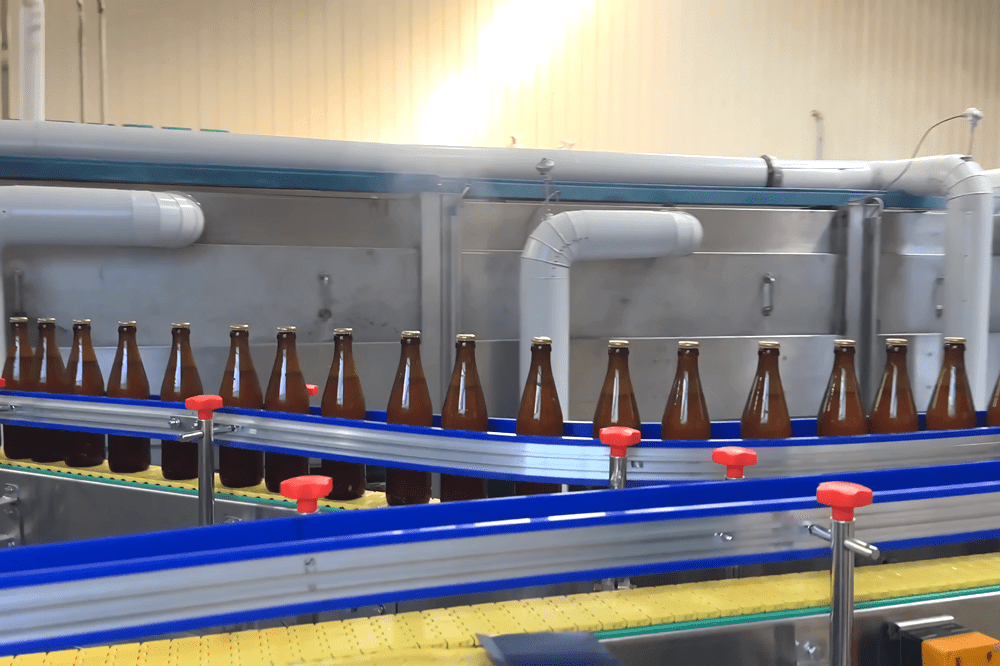

Glass Bottle Craft Beer Filling Capping Machine Line

BCGF series of glass bottled beer filling machine, it is mainly used for beer and craft beer. The final filling temperature is low. The machine design is shorten the time for the beer material contact with outside, increase the sanitation condition throughout economy benefit.

a, washing part

Rotatory bottle-rinsing machine has the functions of not opening the valve and rinsing without bottle, which is working from bottle entrance,bottle transportation,bottle clipping,bottle turning around with synchronously rinsing inside of the bottle to water-dropping and exit have the functions of not opening the valve and rinsing without bottles.

b, filling part

Adopting the way of filling by holding the necks of the bottle, plus the function of pre-cover of the centralizing cover with high precise centralization,which ensure the right seating of mouth of the bottle and filling valve,with low liquid loss.

c, capping part

This series of Automatic Glass Bottle Beer Filling Machine can meet the filling-sealing requirements of different sealing manners for crown cap /screw cap or others.

Adopting crowning the caps with magnetic force,which passes the torque with powerful and constant magnet,and the torque can be adjusted to meet the need of many kind of caps.

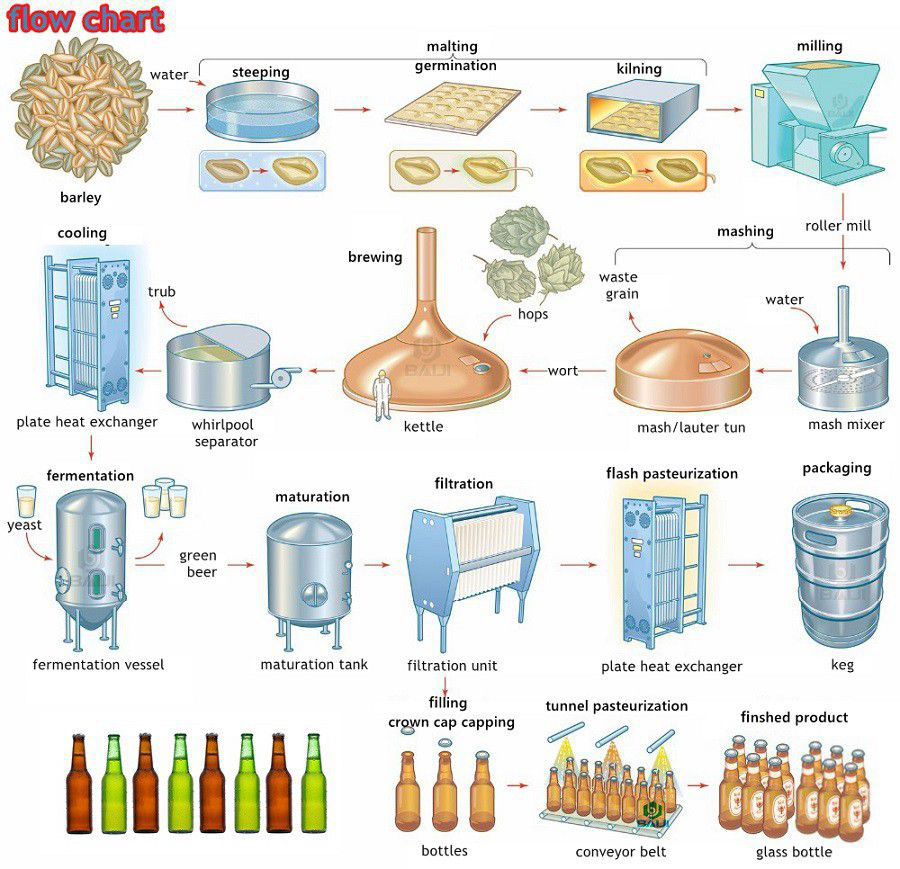

The complete filling process will be as below:

①, The replacement valve is linking with air drum, CO2 inside air drum enter bottles via replacement valve. The gas inside bottle now is mixing with CO2 and air.

②, Air exhausting valve is opened via cam to exhaust the mixed gas.

③, Refill CO2 into bottle again.

④, Operation valve open, after the pressure between cylinder and bottle is equal, the filling process starts, when the filling level reach air returning pipe, filling stops, filling valves closed.

⑤, After filling process finishing, before filling valves leaving bottles, air exhausting valve exhaust extra gas, then filling valves leave bottle neck, filling process finishes.

| Model | BGF14-12-5 | BGF18-18-6 | BGF24-24-8 | BGF32-32-8 |

| Capacity(B/H) | 1500-2000 | 3000-4000 | 5000-6000 | 7000-8000 |

| Application | craft beer / pasteurized beer | |||

| Filling way | isobaric filling | |||

| Suitable bottle size(mm) | H=170-320, D=50-100 (330-1500ml) | |||

| Power(kw) | 4 | 5 | 6 | 8 |

| Weight(kg) | 2200 | 2600 | 4200 | 6000 |

| Dimension(mm) | 2230*1630*2250 | 2360*1830*2250 | 2900*2200*2250 | 3880*2200*2250 |

Beer sterilizer

including heating, sterilization and cooling section.

Automatic adhesive stick labeling machine

We have different model for your different request, such as single side labeling machine, double sides labeling machine and three sides labeling machine.

Automatic carton box packing machine

To pack several bottles into one package, make it easier for delivery.

You can have different group style, 12 bottles one package, 6 bottles one package, etc. It is changeable.