Product Category

- Water filling machine

- Juice drink filling machine

- Soft drink filling machine

- Easy open can filling machine

- Glass bottle filling machine

- 3&5 gallon filling machine

- Beer filling machine

- Oil filling machine

- Bottle blow molding machine

- Blowing filling capping combiblock machine

- Bottle labeling machine

- Finished product packing machine

- Injection molding machine

- Material

- Accessory equipment

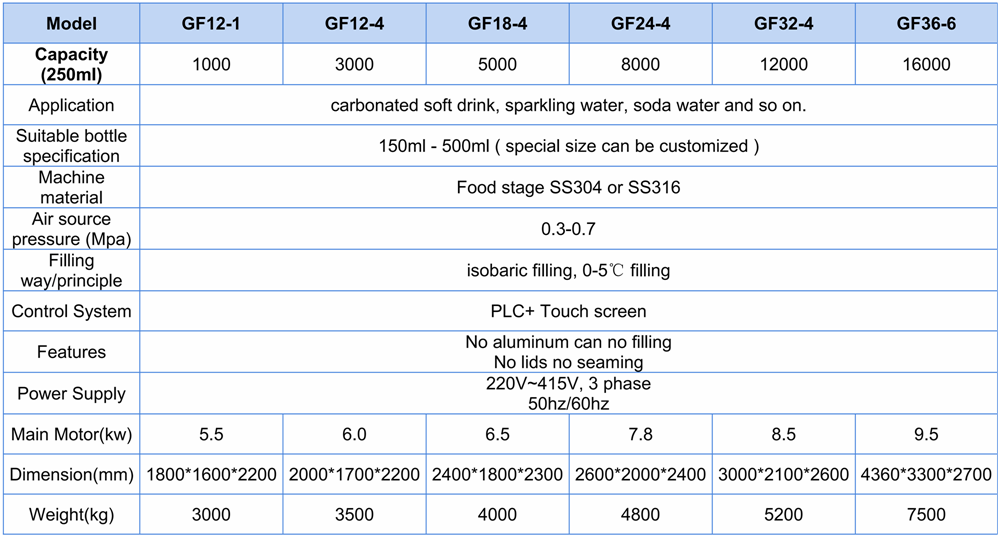

Automatic Aluminum Can Carbonated Soft Drink Beer Beverage Canning Filling Machine

Carbonated drink mixer

It can improve the proportion of water, syrup and carbon dioxide. It is used in carbonated beverage production line and sparkling wine. It is used to cooling the water before mixing which is connected with the mixer.

Aluminum can depalletizer, it is designed to handle empty cans from pallets and transfer, layer by layer, onto the production line.

Aluminum can washing, it is revolution inclined type can washer.

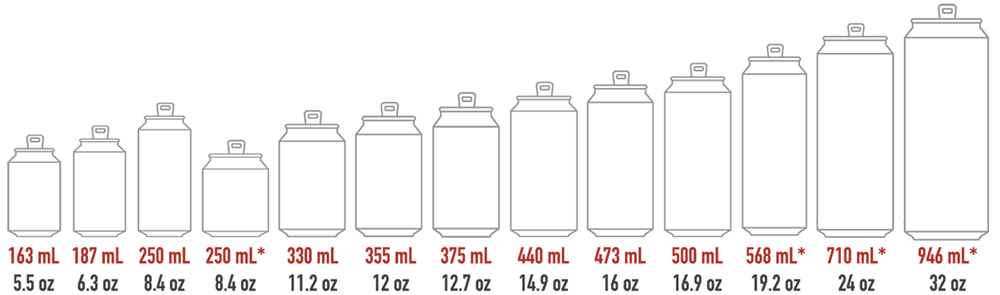

Carbonated soft drink, 0-5℃ filling, isobaric filling

We can provide different models filling unit according to your speed needs. Min. 1000cph, Max. 24000cph.

Can warmer

It is used to warm can after low temperature filling, as the carbonated drink after filling, its bottle touch the outside air, it will has a lot small water drops outside, use this machine will warmer it to normal temperature, and after dryer machine, it will be good for packing.

Automatic PE film wrapping machine

To pack several cans into one package, make it easier for delivery.

You can have different group style, 24 cans one package, 12 cans one package, etc. It is changeable.