Product Category

- Water filling machine

- Juice drink filling machine

- Soft drink filling machine

- Easy open can filling machine

- Glass bottle filling machine

- 3&5 gallon filling machine

- Beer filling machine

- Oil filling machine

- Bottle blow molding machine

- Blowing filling capping combiblock machine

- Bottle labeling machine

- Finished product packing machine

- Injection molding machine

- Material

- Accessory equipment

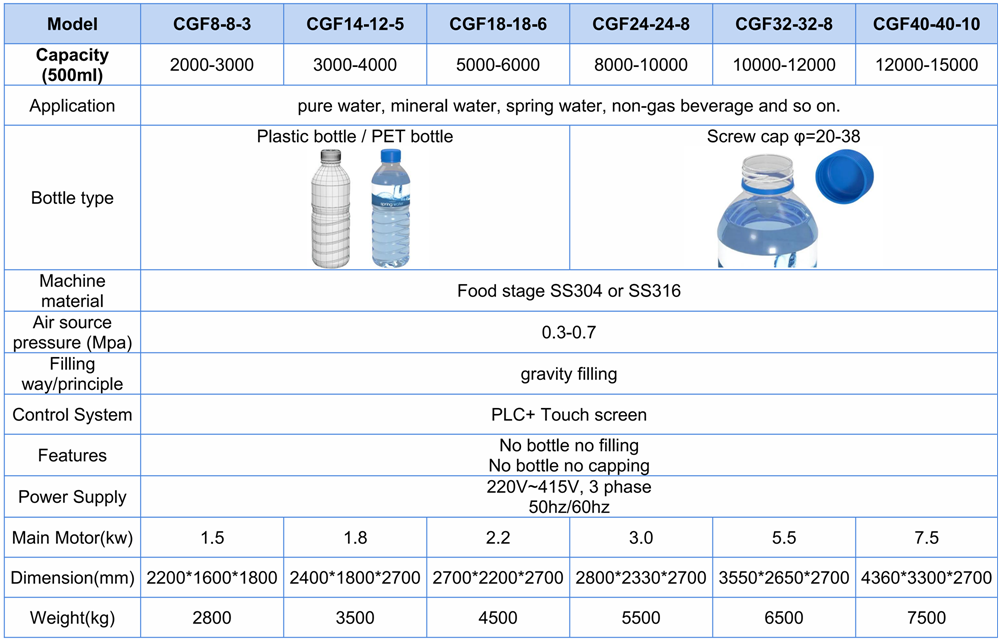

3 In 1 Small PET Bottle Mineral Water Filling Capping Bottling Machine Price

3 in 1 washing filling and capping machine

Water treatment system

Processing included: quartz sand filter, active carbon filter, sodium ion exchanger, precision filter, RO (Reverse Osmosis), ozone generator, finished water tank

Automatic bottle blowing machine

It is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the pure water bottle, mineral water bottle, carbonated drink bottle, juice hot fill bottle and oil bottle etc.

Automatic shrink sleeve labeling machine

It consists of auto labeling machine, heat shrink tunnel and steam generator.

It adopts international advanced technology, cover the circle label on the pet bottle. And then hot shrinking to fix on the position which bottle body designated.

Automatic PE film wrapping machine

To pack several bottles into one package, make it easier for delivery.

You can have different group style, 24 bottles one package, 12 bottles one package, etc. It is changeable.