Product Category

- Water filling machine

- Juice drink filling machine

- Soft drink filling machine

- Easy open can filling machine

- Glass bottle filling machine

- 3&5 gallon filling machine

- Beer filling machine

- Oil filling machine

- Bottle blow molding machine

- Blowing filling capping combiblock machine

- Bottle labeling machine

- Finished product packing machine

- Injection molding machine

- Material

- Accessory equipment

Automatic Small PET Bottle Fruit Juice Bottling Filling Machine

RCGF24-24-8, 8000 bottles per hour, 200ml~2000ml PET bottle. Standard type of RCGF series hot filling machine is “3-in-1”, aiming at special production condition, one disinfectant rinser can be increased to be 4-in-1 monoblock. This system gives full consideration for beverage’s characteristics (fresh fruit juice and concentrated juice) and main technical requirement of hot filling.

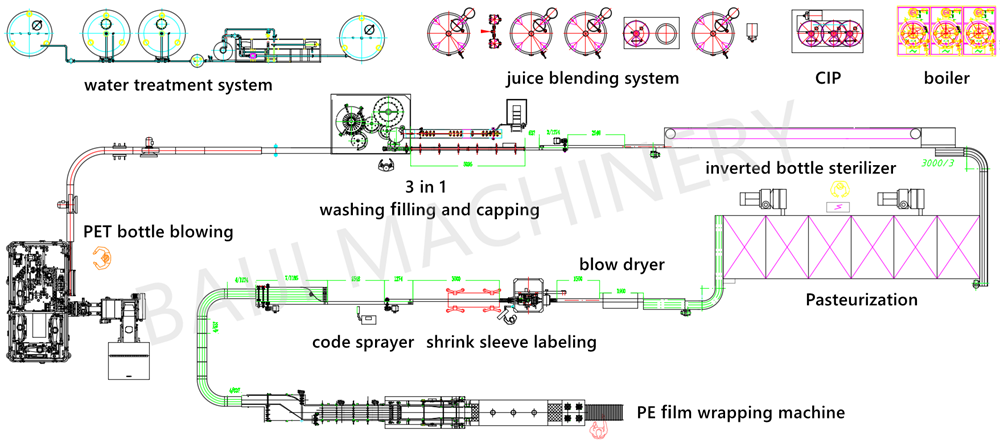

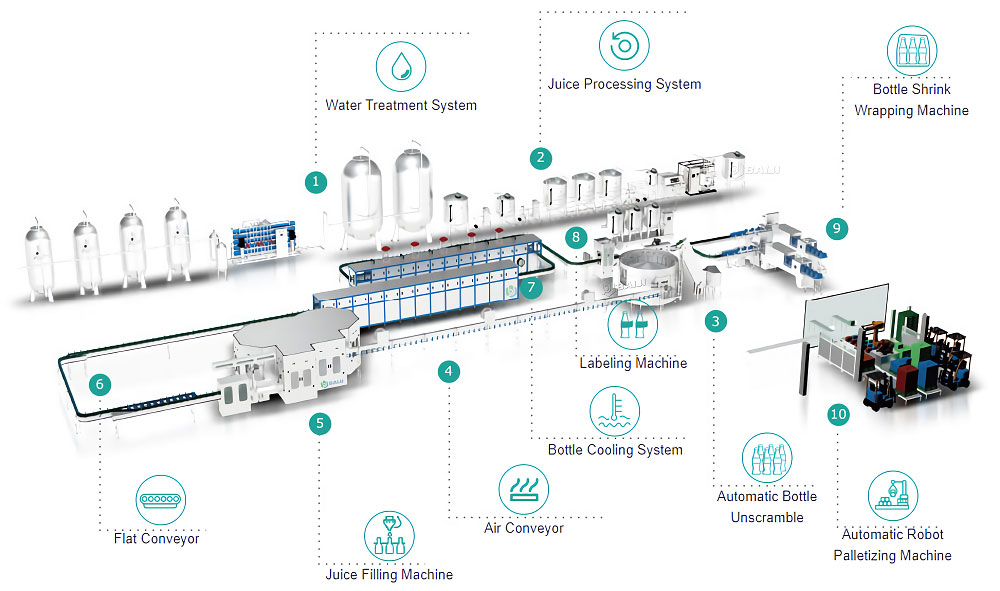

Water treatment system

Processing included: quartz sand filter, active carbon filter, sodium ion exchanger, precision filter, RO (Reverse Osmosis), UV sterilizer, finished water tank

Juice pretreatment system

Fruit juice washing machine → Juice crusher and extractor → Colloid mill → Double filter → sugar melting tank → syrup filter → Blending tank → Double filter → Temporary storage tank → Homogenizer → Temporary storage tank → Vacuum degasser → Super high temperature sterilizer(UHT) → Heat insulation tank

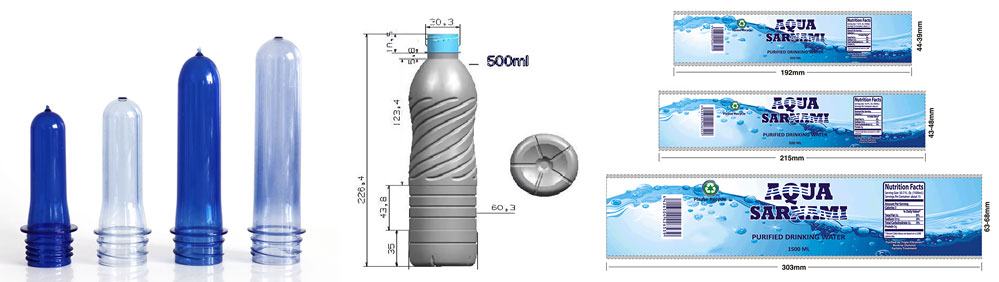

Automatic PET bottle blowing machine

It is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the pure water bottle, mineral water bottle, carbonated drink bottle, juice hot fill bottle and oil bottle etc.

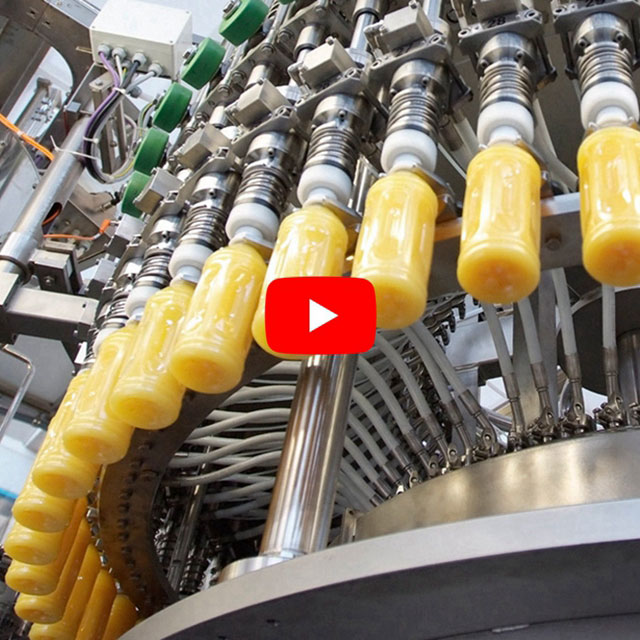

3 in 1 washing filling and capping machine

* If the temperature is low than the setting value, the filling valves will stop and return the last beverage in filling valve to recycle tank and return to UHT again to sterilize with pump.

* Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan’sMitsubishi, France Schneider, OMRON

Pasteurization

It is usually used after fruit juice beverage finished hot filling and sealing, when enter the spray tunnel, the water with the function of high-pressure pump, uniformly spray on the bottle body. The bottles move slowly in the chain, when they are out the tunnel, they can reach the normal temperature, then achieve the purpose of cooling. This machine can also be used for secondary sterilization for fruit juice.

Automatic shrink sleeve labeling machine

It consists of auto labeling machine, heat shrink tunnel and steam generator.

This machine adopts international advanced technology, cover the circle label on the pet bottle.And then hot shrinking to fix on the position which bottle body designated.

Automatic PE film wrapping machine

To pack several bottles into one package, make it easier for delivery.

You can decide 24 bottles one package, 12 bottles one package, etc. It is changeable.

| Model | Capacity (500ml) (BPH) | Power (kw) | Weight (kg) | Dimension (mm) |

| RCGF8-8-3 | 1000-2000 | 1.9 | 1500 | 1900*1420*2000 |

| RCGF14-12-5 | 3000-4000 | 3.5 | 2500 | 2450*1800*2400 |

| RCGF18-18-6 | 5000-7000 | 4.0 | 3500 | 2650*1900*2400 |

| RCGF24-24-8 | 8000-9000 | 4.8 | 4500 | 2900*2100*2400 |

| RCGF32-32-10 | 10000-12000 | 7.6 | 6500 | 4100*2000*2400 |

| RCGF40-40-12 | 12000-15000 | 8.3 | 8500 | 4550*2650*2400 |