Product Category

- Water filling machine

- Juice drink filling machine

- Soft drink filling machine

- Easy open can filling machine

- Glass bottle filling machine

- 3&5 gallon filling machine

- Beer filling machine

- Oil filling machine

- Bottle blow molding machine

- Blowing filling capping combiblock machine

- Bottle labeling machine

- Finished product packing machine

- Injection molding machine

- Material

- Accessory equipment

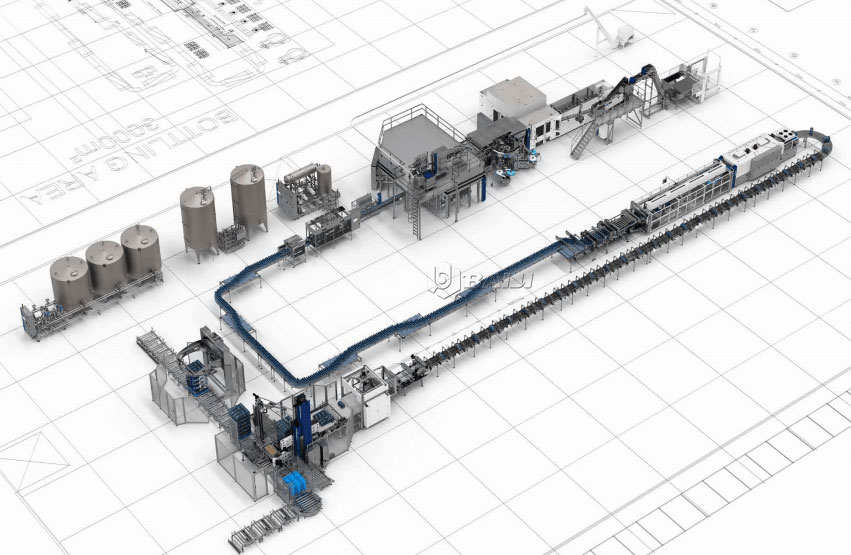

Full Automatic PET Bottle Blowing Filling Capping Combiblock

Application: PET bottle mineral water, PET bottle pure water

Applied containers: PET bottle with various capacities and shapes

Filling system: mechanical valve or flow-meter valve

Capacity: 12000-36000BPH

Product scope: blowing molding system, air compressor system, filling and capping system

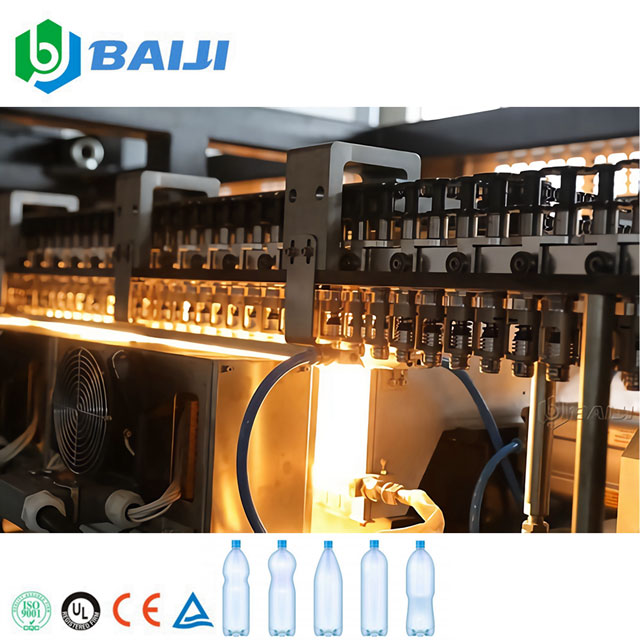

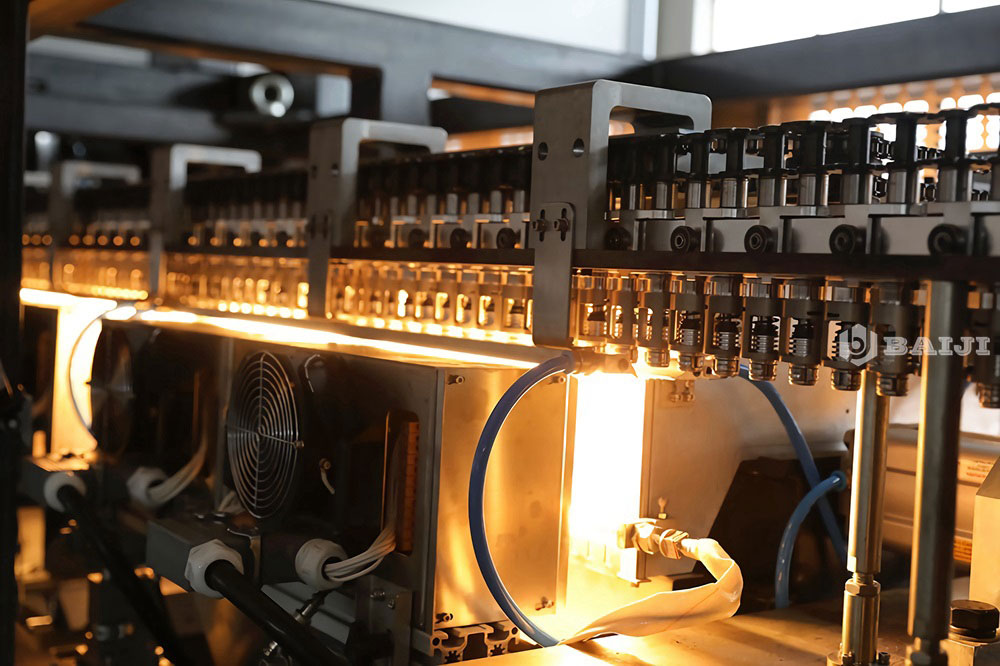

Heating system:

It adopts the matured worldwide-standardized way of preform feed-in and unscrambling, in which preforms go through preform elevator and are transmitted to preform unscrambler. Inside the preform unscrambler, preforms are automatically sorted and delivered by two inclined revolving cylinders with same speed, and the remaining ones will be picked by star wheel and sent back to preform hopper. The whole process of preform unscrambling is fully automatic and has high efficiency without preform scratches.

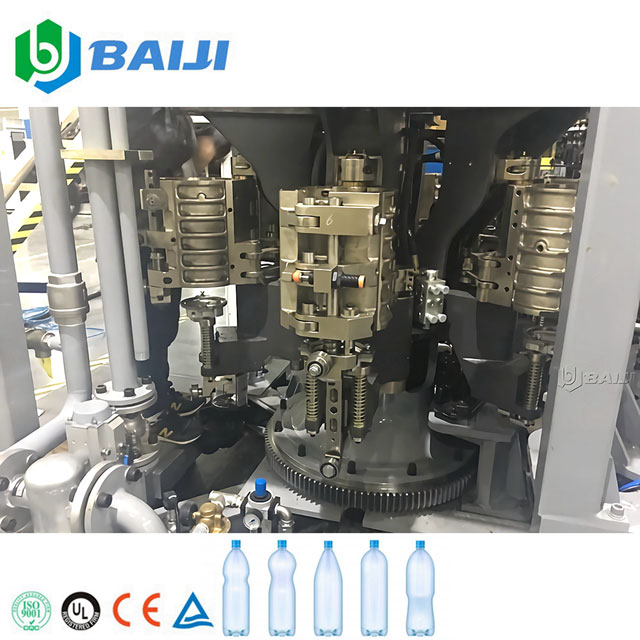

Blowing system:

Special manipulator delivers heated preforms to moulds along certain cam curve. After stretch pre-blow, the preform will be blown to bottles by connecting high pressure compressed air. Special manipular sends the finished bottle out along certain can curve.

| Model | blowing heads | filling heads | capping heads | Capacity ( 500ml, BPH ) |

| 8-24-8 | 8 | 24 | 8 | 12000 |

| 12-32-10 | 12 | 32 | 10 | 18000 |

| 16-40-15 | 16 | 40 | 15 | 24000 |

| 20-60-18 | 20 | 60 | 18 | 36000 |